Micrometer (device) on:

[Wikipedia]

[Google]

[Amazon]

A micrometer, sometimes known as a micrometer screw gauge, is a device incorporating a calibrated

A micrometer, sometimes known as a micrometer screw gauge, is a device incorporating a calibrated

The word ''micrometer'' is a neoclassical coinage . The ''Merriam-Webster Collegiate Dictionary'' says that English got it from French and that its first known appearance in English writing was in 1670. Neither the

The word ''micrometer'' is a neoclassical coinage . The ''Merriam-Webster Collegiate Dictionary'' says that English got it from French and that its first known appearance in English writing was in 1670. Neither the

Each type of micrometer caliper can be fitted with specialized anvils and spindle tips for particular measuring tasks. For example, the anvil may be shaped in the form of a segment of screw thread, in the form of a v-block, or in the form of a large disc.

* Universal micrometer sets come with interchangeable anvils, such as flat, spherical, spline, disk, blade, point, and knife-edge. The term universal micrometer may also refer to a type of micrometer whose frame has modular components, allowing one micrometer to function as outside mic, depth mic, step mic, etc. (often known by the brand names Mul-T-Anvil and Uni-Mike).

* Blade micrometers have a matching set of narrow tips (blades). They allow, for example, the measuring of a narrow o-ring groove.

* Pitch-diameter micrometers (aka thread mics) have a matching set of thread-shaped tips for measuring the pitch diameter of screw threads.

* Limit mics have two anvils and two spindles, and are used like a snap gauge. The part being checked must pass through the first gap and must stop at the second gap in order to be within specification. The two gaps accurately reflect the top and bottom of the tolerance range.

* Bore micrometer, typically a three-anvil head on a micrometer base used to accurately measure inside diameters.

* Tube micrometers have a cylindrical anvil positioned perpendicularly to a spindle and is used to measure the thickness of tubes.

* Micrometer stops are micrometer heads that are mounted on the table of a manual milling machine, bedways of a lathe, or other machine tool, in place of simple stops. They help the operator to position the table or carriage precisely. Stops can also be used to actuate kickout mechanisms or limit switches to halt an automatic feed system.

* Ball micrometers have ball-shaped (

Each type of micrometer caliper can be fitted with specialized anvils and spindle tips for particular measuring tasks. For example, the anvil may be shaped in the form of a segment of screw thread, in the form of a v-block, or in the form of a large disc.

* Universal micrometer sets come with interchangeable anvils, such as flat, spherical, spline, disk, blade, point, and knife-edge. The term universal micrometer may also refer to a type of micrometer whose frame has modular components, allowing one micrometer to function as outside mic, depth mic, step mic, etc. (often known by the brand names Mul-T-Anvil and Uni-Mike).

* Blade micrometers have a matching set of narrow tips (blades). They allow, for example, the measuring of a narrow o-ring groove.

* Pitch-diameter micrometers (aka thread mics) have a matching set of thread-shaped tips for measuring the pitch diameter of screw threads.

* Limit mics have two anvils and two spindles, and are used like a snap gauge. The part being checked must pass through the first gap and must stop at the second gap in order to be within specification. The two gaps accurately reflect the top and bottom of the tolerance range.

* Bore micrometer, typically a three-anvil head on a micrometer base used to accurately measure inside diameters.

* Tube micrometers have a cylindrical anvil positioned perpendicularly to a spindle and is used to measure the thickness of tubes.

* Micrometer stops are micrometer heads that are mounted on the table of a manual milling machine, bedways of a lathe, or other machine tool, in place of simple stops. They help the operator to position the table or carriage precisely. Stops can also be used to actuate kickout mechanisms or limit switches to halt an automatic feed system.

* Ball micrometers have ball-shaped (

Micrometers use the screw to transform small distances* (that are too small to measure directly) into large rotations of the screw that are big enough to read from a scale. The accuracy of a micrometer derives from the accuracy of the thread-forms that are central to the core of its design. In some cases it is a

Micrometers use the screw to transform small distances* (that are too small to measure directly) into large rotations of the screw that are big enough to read from a scale. The accuracy of a micrometer derives from the accuracy of the thread-forms that are central to the core of its design. In some cases it is a

A micrometer is composed of:

; Frame: The C-shaped body that holds the anvil and barrel in constant relation to each other. It is thick because it needs to minimize flexion, expansion, and contraction, which would distort the measurement.The frame is heavy and consequently has a high thermal mass, to prevent substantial heating up by the holding hand/fingers. It is often covered by insulating plastic plates which further reduce heat transference.Explanation: if one holds the frame long enough so that it heats up by 10 °C, then the increase in length of any 10 cm linear piece of steel is of magnitude 1/100 mm. For micrometers this is their typical accuracy range.Micrometers typically have a specified temperature at which the measurement is correct (often 20 °C 8 °F which is generally considered "

A micrometer is composed of:

; Frame: The C-shaped body that holds the anvil and barrel in constant relation to each other. It is thick because it needs to minimize flexion, expansion, and contraction, which would distort the measurement.The frame is heavy and consequently has a high thermal mass, to prevent substantial heating up by the holding hand/fingers. It is often covered by insulating plastic plates which further reduce heat transference.Explanation: if one holds the frame long enough so that it heats up by 10 °C, then the increase in length of any 10 cm linear piece of steel is of magnitude 1/100 mm. For micrometers this is their typical accuracy range.Micrometers typically have a specified temperature at which the measurement is correct (often 20 °C 8 °F which is generally considered "

The spindle of a micrometer graduated for the

The spindle of a micrometer graduated for the

The spindle of an ordinary metric micrometer has 2 threads per millimetre, and thus one complete revolution moves the spindle through a distance of 0.5 millimeter. The longitudinal line on the sleeve is graduated with 1 millimetre divisions and 0.5 millimetre subdivisions. The thimble has 50 graduations, each being 0.01 millimetre (one-hundredth of a millimetre). Thus, the reading is given by the number of millimetre divisions visible on the scale of the sleeve plus the division on the thimble which coincides with the axial line on the sleeve.

As shown in the image, suppose that the thimble were screwed out so that graduation 5, and one additional 0.5 subdivision were visible on the sleeve. The reading from the axial line on the sleeve almost reaches graduation 28 on the thimble. The best estimate is 27.9 graduations. The reading then would be 5.00 (exact) + 0.5 (exact) + 0.279 (estimate) = 5.779 mm (estimate). As the last digit is an "estimated tenth", both 5.780 mm and 5.778 mm are also reasonably acceptable readings but the former cannot be written as 5.78 mm or, by the rules for

The spindle of an ordinary metric micrometer has 2 threads per millimetre, and thus one complete revolution moves the spindle through a distance of 0.5 millimeter. The longitudinal line on the sleeve is graduated with 1 millimetre divisions and 0.5 millimetre subdivisions. The thimble has 50 graduations, each being 0.01 millimetre (one-hundredth of a millimetre). Thus, the reading is given by the number of millimetre divisions visible on the scale of the sleeve plus the division on the thimble which coincides with the axial line on the sleeve.

As shown in the image, suppose that the thimble were screwed out so that graduation 5, and one additional 0.5 subdivision were visible on the sleeve. The reading from the axial line on the sleeve almost reaches graduation 28 on the thimble. The best estimate is 27.9 graduations. The reading then would be 5.00 (exact) + 0.5 (exact) + 0.279 (estimate) = 5.779 mm (estimate). As the last digit is an "estimated tenth", both 5.780 mm and 5.778 mm are also reasonably acceptable readings but the former cannot be written as 5.78 mm or, by the rules for

Some micrometers are provided with a

Some micrometers are provided with a

ASTM, SAE,

micrometer simulator with zero error.Print files including lessons and quizzes for teachers and students of the subject matter.

* ttp://www.miniphysics.com/how-to-read-a-micrometer-screw-gauge.html How to read a micrometer screw gaugebr>How its made, micrometer

{{Authority control Length, distance, or range measuring devices

A micrometer, sometimes known as a micrometer screw gauge, is a device incorporating a calibrated

A micrometer, sometimes known as a micrometer screw gauge, is a device incorporating a calibrated screw

A screw and a bolt (see '' Differentiation between bolt and screw'' below) are similar types of fastener typically made of metal and characterized by a helical ridge, called a ''male thread'' (external thread). Screws and bolts are used to fa ...

widely used for accurate

Accuracy and precision are two measures of '' observational error''.

''Accuracy'' is how close a given set of measurements ( observations or readings) are to their ''true value'', while ''precision'' is how close the measurements are to each ot ...

measurement of components in mechanical engineering

Mechanical engineering is the study of physical machines that may involve force and movement. It is an engineering branch that combines engineering physics and mathematics principles with materials science, to design, analyze, manufacture, and ...

and machining

Machining is a process in which a material (often metal) is cut to a desired final shape and size by a controlled material-removal process. The processes that have this common theme are collectively called subtractive manufacturing, which utilizes ...

as well as most mechanical trades, along with other metrological

Metrology is the scientific study of measurement. It establishes a common understanding of units, crucial in linking human activities. Modern metrology has its roots in the French Revolution's political motivation to standardise units in Fra ...

instruments such as dial, vernier, and digital calipers. Micrometers are usually, but not always, in the form of caliper

A caliper (British spelling also calliper, or in plurale tantum sense a pair of calipers) is a device used to measure the dimensions of an object.

Many types of calipers permit reading out a measurement on a ruled scale, a dial, or a digital d ...

s (opposing ends joined by a frame). The spindle is a very accurately machined screw and the object to be measured is placed between the spindle and the anvil. The spindle is moved by turning the ratchet knob or thimble until the object to be measured is lightly touched by both the spindle and the anvil.

Micrometers are also used in telescopes or microscopes to measure the apparent diameter of celestial bodies or microscopic objects. The micrometer used with a telescope was invented about 1638 by William Gascoigne, an English astronomer.

History

metre

The metre (British spelling) or meter (American spelling; see spelling differences) (from the French unit , from the Greek noun , "measure"), symbol m, is the primary unit of length in the International System of Units (SI), though its pref ...

nor the micrometre

The micrometre ( international spelling as used by the International Bureau of Weights and Measures; SI symbol: μm) or micrometer (American spelling), also commonly known as a micron, is a unit of length in the International System of Unit ...

(μm) nor the micrometer (device) as we know them today existed at that time. However, the people of that time did have much need for, and interest in, the ability to measure small things and small differences. The word was no doubt coined in reference to this endeavor, even if it did not refer specifically to its present-day senses.

The first ever micrometric screw was invented by William Gascoigne in the 17th century, as an enhancement of the vernier; it was used in a telescope to measure angular distances between stars and the relative sizes of celestial objects.

Henry Maudslay

Henry Maudslay ( pronunciation and spelling) (22 August 1771 – 14 February 1831) was an English machine tool innovator, tool and die maker, and inventor. He is considered a founding father of machine tool technology. His inventions were ...

built a bench micrometer in the early 19th century that was jocularly nicknamed "the Lord Chancellor" among his staff because it was the final judge on measurement accuracy and precision

Accuracy and precision are two measures of ''observational error''.

''Accuracy'' is how close a given set of measurements ( observations or readings) are to their ''true value'', while ''precision'' is how close the measurements are to each oth ...

in the firm's work. In 1844, details of Whitworth's workshop micrometer were published. This was described as having a strong frame of cast iron, the opposite ends of which were two highly finished steel cylinders, which traversed longitudinally by action of screws. The ends of the cylinders where they met was of hemispherical shape. One screw was fitted with a wheel graduated to measure to the ten thousandth of an inch. His object was ''to furnish ordinary mechanics with an instrument which, while it afforded very accurate indications, was yet not very liable to be deranged by the rough handling of the workshop''.

The first documented development of handheld micrometer-screw caliper

A caliper (British spelling also calliper, or in plurale tantum sense a pair of calipers) is a device used to measure the dimensions of an object.

Many types of calipers permit reading out a measurement on a ruled scale, a dial, or a digital d ...

s was by Jean Laurent Palmer

Jean may refer to:

People

* Jean (female given name)

* Jean (male given name)

* Jean (surname)

Fictional characters

* Jean Grey, a Marvel Comics character

* Jean Valjean, fictional character in novel ''Les Misérables'' and its adaptations

* J ...

of Paris

Paris () is the capital and most populous city of France, with an estimated population of 2,165,423 residents in 2019 in an area of more than 105 km² (41 sq mi), making it the 30th most densely populated city in the world in 2020. S ...

in 1848; the device is therefore often called ''palmer'' in French, ''tornillo de Palmer'' ("Palmer screw") in Spanish, and ''calibro Palmer'' ("Palmer caliper") in Italian. (Those languages also use the ''micrometer'' cognates: ''micromètre, micrómetro, micrometro''.) The micrometer caliper was introduced to the mass market in anglophone countries by Brown & Sharpe Brown & Sharpe is a division of Hexagon AB, a Swedish multinational corporation focused mainly on metrological tools and technology. During the 19th and 20th centuries, Brown & Sharpe was one of the best-known and most influential machine tool build ...

in 1867, allowing the penetration of the instrument's use into the average machine shop. Brown & Sharpe were inspired by several earlier devices, one of them being Palmer's design. In 1888, Edward W. Morley added to the precision of micrometric measurements and proved their accuracy in a complex series of experiments.

The culture of toolroom

Tool and die makers are highly skilled crafters working in the manufacturing industries. Variations on the name include tool maker, toolmaker, die maker, diemaker, mold maker, moldmaker or tool jig and die-maker depending on which area of concen ...

accuracy and precision, which started with interchangeability

Interchangeability can refer to:

*Interchangeable parts

Interchangeable parts are parts (components) that are identical for practical purposes. They are made to specifications that ensure that they are so nearly identical that they will fit into ...

pioneers including Gribeauval

Lieutenant General Jean-Baptiste Vaquette de Gribeauval (15 September 1715 – 9 May 1789) was a French artillery officer and engineer who revolutionised the French cannon, creating a new production system that allowed for lighter, more uniform g ...

, Tousard, North

North is one of the four compass points or cardinal directions. It is the opposite of south and is perpendicular to east and west. ''North'' is a noun, adjective, or adverb indicating Direction (geometry), direction or geography.

Etymology

T ...

, Hall, Whitney Whitney may refer to:

Film and television

* ''Whitney'' (2015 film), a Whitney Houston biopic starring Yaya DaCosta

* ''Whitney'' (2018 film), a documentary about Whitney Houston

* ''Whitney'' (TV series), an American sitcom that premiered i ...

, and Colt

Colt(s) or COLT may refer to:

*Colt (horse), an intact (uncastrated) male horse under four years of age

People

* Colt (given name)

*Colt (surname)

Places

*Colt, Arkansas, United States

*Colt, Louisiana, an unincorporated community, United States ...

, and continued through leaders such as Maudslay, Palmer, Whitworth, Brown, Sharpe, Pratt

Pratt is an English surname. Notable people with the surname include:

A–F

* Abner Pratt (1801–1863), American diplomat, jurist, politician, lawyer

* Al Pratt (baseball) (1847–1937), American baseball player

* Andy Pratt (baseball) (bor ...

, Whitney Whitney may refer to:

Film and television

* ''Whitney'' (2015 film), a Whitney Houston biopic starring Yaya DaCosta

* ''Whitney'' (2018 film), a documentary about Whitney Houston

* ''Whitney'' (TV series), an American sitcom that premiered i ...

, Leland, and others, grew during the Machine Age

The Machine Age is an era that includes the early-to-mid 20th century, sometimes also including the late 19th century. An approximate dating would be about 1880 to 1945. Considered to be at its peak in the time between the first and second wo ...

to become an important part of combining applied science

Applied science is the use of the scientific method and knowledge obtained via conclusions from the method to attain practical goals. It includes a broad range of disciplines such as engineering and medicine. Applied science is often contrasted ...

with technology

Technology is the application of knowledge to reach practical goals in a specifiable and reproducible way. The word ''technology'' may also mean the product of such an endeavor. The use of technology is widely prevalent in medicine, science, ...

. Beginning in the early 20th century, one could no longer truly master tool and die making, machine tool

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All ...

building, or engineering

Engineering is the use of scientific method, scientific principles to design and build machines, structures, and other items, including bridges, tunnels, roads, vehicles, and buildings. The discipline of engineering encompasses a broad rang ...

without some knowledge of the science of metrology, as well as the sciences of chemistry and physics (for metallurgy

Metallurgy is a domain of materials science and engineering that studies the physical and chemical behavior of metallic elements, their inter-metallic compounds, and their mixtures, which are known as alloys.

Metallurgy encompasses both the sc ...

, kinematics

Kinematics is a subfield of physics, developed in classical mechanics, that describes the Motion (physics), motion of points, Physical object, bodies (objects), and systems of bodies (groups of objects) without considering the forces that cause ...

/ dynamics, and quality

Quality may refer to:

Concepts

*Quality (business), the ''non-inferiority'' or ''superiority'' of something

*Quality (philosophy), an attribute or a property

*Quality (physics), in response theory

* Energy quality, used in various science discipl ...

).

Types

Specialized types

Each type of micrometer caliper can be fitted with specialized anvils and spindle tips for particular measuring tasks. For example, the anvil may be shaped in the form of a segment of screw thread, in the form of a v-block, or in the form of a large disc.

* Universal micrometer sets come with interchangeable anvils, such as flat, spherical, spline, disk, blade, point, and knife-edge. The term universal micrometer may also refer to a type of micrometer whose frame has modular components, allowing one micrometer to function as outside mic, depth mic, step mic, etc. (often known by the brand names Mul-T-Anvil and Uni-Mike).

* Blade micrometers have a matching set of narrow tips (blades). They allow, for example, the measuring of a narrow o-ring groove.

* Pitch-diameter micrometers (aka thread mics) have a matching set of thread-shaped tips for measuring the pitch diameter of screw threads.

* Limit mics have two anvils and two spindles, and are used like a snap gauge. The part being checked must pass through the first gap and must stop at the second gap in order to be within specification. The two gaps accurately reflect the top and bottom of the tolerance range.

* Bore micrometer, typically a three-anvil head on a micrometer base used to accurately measure inside diameters.

* Tube micrometers have a cylindrical anvil positioned perpendicularly to a spindle and is used to measure the thickness of tubes.

* Micrometer stops are micrometer heads that are mounted on the table of a manual milling machine, bedways of a lathe, or other machine tool, in place of simple stops. They help the operator to position the table or carriage precisely. Stops can also be used to actuate kickout mechanisms or limit switches to halt an automatic feed system.

* Ball micrometers have ball-shaped (

Each type of micrometer caliper can be fitted with specialized anvils and spindle tips for particular measuring tasks. For example, the anvil may be shaped in the form of a segment of screw thread, in the form of a v-block, or in the form of a large disc.

* Universal micrometer sets come with interchangeable anvils, such as flat, spherical, spline, disk, blade, point, and knife-edge. The term universal micrometer may also refer to a type of micrometer whose frame has modular components, allowing one micrometer to function as outside mic, depth mic, step mic, etc. (often known by the brand names Mul-T-Anvil and Uni-Mike).

* Blade micrometers have a matching set of narrow tips (blades). They allow, for example, the measuring of a narrow o-ring groove.

* Pitch-diameter micrometers (aka thread mics) have a matching set of thread-shaped tips for measuring the pitch diameter of screw threads.

* Limit mics have two anvils and two spindles, and are used like a snap gauge. The part being checked must pass through the first gap and must stop at the second gap in order to be within specification. The two gaps accurately reflect the top and bottom of the tolerance range.

* Bore micrometer, typically a three-anvil head on a micrometer base used to accurately measure inside diameters.

* Tube micrometers have a cylindrical anvil positioned perpendicularly to a spindle and is used to measure the thickness of tubes.

* Micrometer stops are micrometer heads that are mounted on the table of a manual milling machine, bedways of a lathe, or other machine tool, in place of simple stops. They help the operator to position the table or carriage precisely. Stops can also be used to actuate kickout mechanisms or limit switches to halt an automatic feed system.

* Ball micrometers have ball-shaped (spherical

A sphere () is a geometrical object that is a three-dimensional analogue to a two-dimensional circle. A sphere is the set of points that are all at the same distance from a given point in three-dimensional space.. That given point is the ce ...

) anvils. They may have one flat and one ball anvil, in which case they are used for measuring tube wall thickness, distance of a hole to an edge, and other distances where one anvil must be placed against a rounded surface. They differ in application from tube micrometers in that they may be used to measure against rounded surfaces which are not tubes, but the ball anvil may also not be able to fit into smaller tubes as easily as a tube micrometer. Ball micrometers with a pair of balls can be used when single-tangential-point contact is desired on both sides. The most common example is in measuring the pitch diameter of screw threads (which is also done with conical anvils or the 3-wire method, the latter of which uses similar geometry as the pair-of-balls approach).

* Bench micrometers are tools for inspection use whose accuracy and precision

Accuracy and precision are two measures of ''observational error''.

''Accuracy'' is how close a given set of measurements ( observations or readings) are to their ''true value'', while ''precision'' is how close the measurements are to each oth ...

are around half a micrometre (20 millionths of an inch, "a fifth of a tenth" in machinist jargon) and whose repeatability is around a quarter micrometre ("a tenth of a tenth"). An example is the Pratt & Whitney Supermicrometer brand.

* Digit mics are the type with mechanical digits that roll over.

* Digital mics are the type that uses an encoder to detect the distance and displays the result on a digital screen.

* V mics are outside mics with a small V-block for an anvil. They are useful for measuring the diameter of a circle from three points evenly spaced around it (versus the two points of a standard outside micrometer). An example of when this is necessary is measuring the diameter of 3-flute endmills and twist drills.

Operating principles

Micrometers use the screw to transform small distances* (that are too small to measure directly) into large rotations of the screw that are big enough to read from a scale. The accuracy of a micrometer derives from the accuracy of the thread-forms that are central to the core of its design. In some cases it is a

Micrometers use the screw to transform small distances* (that are too small to measure directly) into large rotations of the screw that are big enough to read from a scale. The accuracy of a micrometer derives from the accuracy of the thread-forms that are central to the core of its design. In some cases it is a differential screw

A differential screw is a mechanism (engineering), mechanism used for making small, precise adjustments to the spacing between two objects (such as in focusing a microscope, moving the anvils of a Micrometer (device), micrometer, or positioning ...

. The basic operating principles of a micrometer are as follows:

# The amount of rotation of an accurately made screw can be directly and precisely correlated to a certain amount of axial movement (and vice versa), through the constant known as the screw's ''lead

Lead is a chemical element with the symbol Pb (from the Latin ) and atomic number 82. It is a heavy metal that is denser than most common materials. Lead is soft and malleable, and also has a relatively low melting point. When freshly cu ...

'' (). A screw's ''lead'' is the distance it moves forward axially with one complete turn (360 °). (In most threads hat is, in all single-start threads ''lead'' and ''pitch'' refer to essentially the same concept.)

# With an appropriate lead and major diameter of the screw, a given amount of axial movement will be ''amplified'' in the resulting circumferential movement.

For example, if the lead of a screw is 1 mm, but the major diameter (here, outer diameter) is 10 mm, then the circumference of the screw is 10π, or about 31.4 mm. Therefore, an axial movement of 1 mm is amplified (magnified) to a circumferential movement of 31.4 mm. This amplification allows a small difference in the sizes of two similar measured objects to correlate to a larger difference in the position of a micrometer's thimble. In some micrometers, even greater accuracy is obtained by using a differential screw

A differential screw is a mechanism (engineering), mechanism used for making small, precise adjustments to the spacing between two objects (such as in focusing a microscope, moving the anvils of a Micrometer (device), micrometer, or positioning ...

adjuster to move the thimble in much smaller increments than a single thread would allow.

In classic-style analog micrometers, the position of the thimble is read directly from scale markings on the thimble and sleeve (for names of parts see next section). A vernier scale

A vernier scale, named after Pierre Vernier, is a visual aid to take an accurate measurement reading between two graduation markings on a linear scale by using mechanical interpolation, thereby increasing resolution and reducing measurement unce ...

is often included, which allows the position to be read to a fraction of the smallest scale mark. In digital micrometers, an electronic readout displays the length digitally on an LCD on the instrument. There also exist mechanical-digit versions, like the style of car odometer

An odometer or odograph is an instrument used for measuring the distance traveled by a vehicle, such as a bicycle or car. The device may be electronic, mechanical, or a combination of the two (electromechanical). The noun derives from ancient Gr ...

s where the numbers "roll over".

Parts

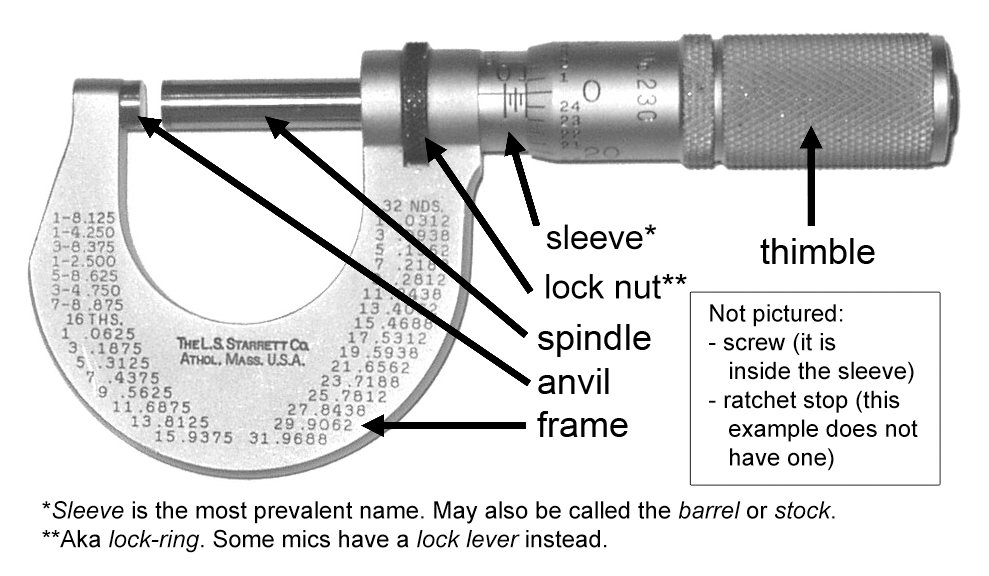

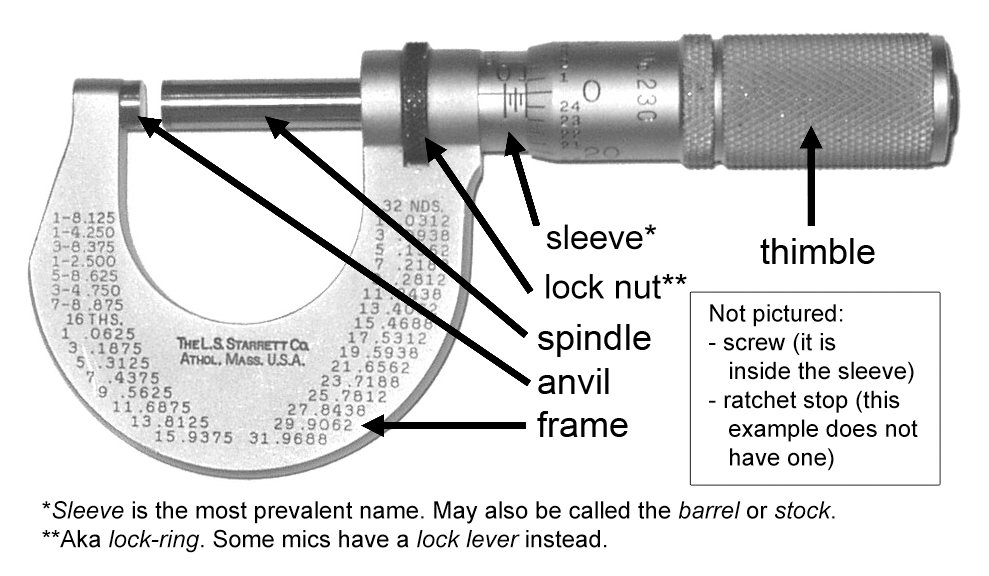

A micrometer is composed of:

; Frame: The C-shaped body that holds the anvil and barrel in constant relation to each other. It is thick because it needs to minimize flexion, expansion, and contraction, which would distort the measurement.The frame is heavy and consequently has a high thermal mass, to prevent substantial heating up by the holding hand/fingers. It is often covered by insulating plastic plates which further reduce heat transference.Explanation: if one holds the frame long enough so that it heats up by 10 °C, then the increase in length of any 10 cm linear piece of steel is of magnitude 1/100 mm. For micrometers this is their typical accuracy range.Micrometers typically have a specified temperature at which the measurement is correct (often 20 °C 8 °F which is generally considered "

A micrometer is composed of:

; Frame: The C-shaped body that holds the anvil and barrel in constant relation to each other. It is thick because it needs to minimize flexion, expansion, and contraction, which would distort the measurement.The frame is heavy and consequently has a high thermal mass, to prevent substantial heating up by the holding hand/fingers. It is often covered by insulating plastic plates which further reduce heat transference.Explanation: if one holds the frame long enough so that it heats up by 10 °C, then the increase in length of any 10 cm linear piece of steel is of magnitude 1/100 mm. For micrometers this is their typical accuracy range.Micrometers typically have a specified temperature at which the measurement is correct (often 20 °C 8 °F which is generally considered "room temperature

Colloquially, "room temperature" is a range of air temperatures that most people prefer for indoor settings. It feels comfortable to a person when they are wearing typical indoor clothing. Human comfort can extend beyond this range depending on ...

" in a room with HVAC

Heating, ventilation, and air conditioning (HVAC) is the use of various technologies to control the temperature, humidity, and purity of the air in an enclosed space. Its goal is to provide thermal comfort and acceptable indoor air quality. HV ...

). Toolroom

Tool and die makers are highly skilled crafters working in the manufacturing industries. Variations on the name include tool maker, toolmaker, die maker, diemaker, mold maker, moldmaker or tool jig and die-maker depending on which area of concen ...

s are generally kept at 20 °C 8 °F

; Anvil: The shiny part that the spindle moves toward, and that the sample rests against.

; Sleeve, barrel, or stock: The stationary round component with the linear scale on it, sometimes with vernier markings. In some instruments the scale is marked on a tight-fitting but movable cylindrical sleeve fitting over the internal fixed barrel. This allows zeroing to be done by slightly altering the position of the sleeve.

; Lock nut, lock-ring, or thimble lock: The knurled component (or lever) that one can tighten to hold the spindle stationary, such as when momentarily holding a measurement.

; Screw: (Not visible) The heart of the micrometer, as explained under "Operating principles". It is inside the barrel. This references the fact that the usual name for the device in German is ''Messschraube'', literally "measuring screw".

; Spindle: The shiny cylindrical component that the thimble causes to move toward the anvil.

; Thimble: The component that one's thumb turns. Graduated markings.

; Ratchet stop: (Not illustrated) Device on end of handle that limits applied pressure by slipping at a calibrated torque.

Reading

Micrometers are high precision instruments. Proper use of them requires not only understanding their operation itself but also the nature of the object and the dynamic between the instrument and the object as it is being measured. For simplicity's sake, in the figures and text below issues related to deformation or definition of the length being measured are assumed to be negligible unless otherwise stated.Customary/Imperial system

The spindle of a micrometer graduated for the

The spindle of a micrometer graduated for the Imperial and US customary measurement systems

The imperial and US customary measurement systems are both derived from an earlier English system of measurement which in turn can be traced back to Ancient Roman units of measurement, and Carolingian and Saxon units of measure.

The US Cust ...

has 40 threads per inch, so that one turn moves the spindle axially 0.025 inch (1 ÷ 40 = 0.025), equal to the distance between adjacent graduations on the sleeve. The 25 graduations on the thimble allow the 0.025 inch to be further divided, so that turning the thimble through one division moves the spindle axially 0.001 inch (0.025 ÷ 25 = 0.001). Thus, the reading is given by the number of whole divisions that are visible on the scale of the sleeve, multiplied by 25 (the number of thousandths of an inch that each division represents), plus the number of that division on the thimble which coincides with the axial zero line on the sleeve. The result will be the diameter expressed in thousandths of an inch. As the numbers 1, 2, 3, etc., appear below every fourth sub-division on the sleeve, indicating hundreds of thousandths, the reading can easily be taken.

Suppose the thimble were screwed out so that graduation 2, and three additional sub-divisions, were visible on the sleeve (as shown in the image), and that graduation 1 on the thimble coincided with the axial line on the sleeve. The reading would then be 0.2000 + 0.075 + 0.001, or 0.276 inch.

Metric system

The spindle of an ordinary metric micrometer has 2 threads per millimetre, and thus one complete revolution moves the spindle through a distance of 0.5 millimeter. The longitudinal line on the sleeve is graduated with 1 millimetre divisions and 0.5 millimetre subdivisions. The thimble has 50 graduations, each being 0.01 millimetre (one-hundredth of a millimetre). Thus, the reading is given by the number of millimetre divisions visible on the scale of the sleeve plus the division on the thimble which coincides with the axial line on the sleeve.

As shown in the image, suppose that the thimble were screwed out so that graduation 5, and one additional 0.5 subdivision were visible on the sleeve. The reading from the axial line on the sleeve almost reaches graduation 28 on the thimble. The best estimate is 27.9 graduations. The reading then would be 5.00 (exact) + 0.5 (exact) + 0.279 (estimate) = 5.779 mm (estimate). As the last digit is an "estimated tenth", both 5.780 mm and 5.778 mm are also reasonably acceptable readings but the former cannot be written as 5.78 mm or, by the rules for

The spindle of an ordinary metric micrometer has 2 threads per millimetre, and thus one complete revolution moves the spindle through a distance of 0.5 millimeter. The longitudinal line on the sleeve is graduated with 1 millimetre divisions and 0.5 millimetre subdivisions. The thimble has 50 graduations, each being 0.01 millimetre (one-hundredth of a millimetre). Thus, the reading is given by the number of millimetre divisions visible on the scale of the sleeve plus the division on the thimble which coincides with the axial line on the sleeve.

As shown in the image, suppose that the thimble were screwed out so that graduation 5, and one additional 0.5 subdivision were visible on the sleeve. The reading from the axial line on the sleeve almost reaches graduation 28 on the thimble. The best estimate is 27.9 graduations. The reading then would be 5.00 (exact) + 0.5 (exact) + 0.279 (estimate) = 5.779 mm (estimate). As the last digit is an "estimated tenth", both 5.780 mm and 5.778 mm are also reasonably acceptable readings but the former cannot be written as 5.78 mm or, by the rules for significant figure

Significant figures (also known as the significant digits, ''precision'' or ''resolution'') of a number in positional notation are digits in the number that are reliable and necessary to indicate the quantity of something.

If a number expre ...

s, it is then taken to express ten times less precision than the instrument actually has! But note that the nature of the object being measured often requires one should round the result to fewer significant figures than which the instrument is capable.

Vernier micrometers

Some micrometers are provided with a

Some micrometers are provided with a vernier scale

A vernier scale, named after Pierre Vernier, is a visual aid to take an accurate measurement reading between two graduation markings on a linear scale by using mechanical interpolation, thereby increasing resolution and reducing measurement unce ...

on the sleeve in addition to the regular graduations. These permit measurements within 0.001millimetre to be made on metric micrometers, or 0.0001 inches on inch-system micrometers.

The additional digit of these micrometers is obtained by finding the line on the sleeve vernier scale which exactly coincides with one on the thimble. The number of this coinciding vernier line represents the additional digit.

Thus, the reading for metric micrometers of this type is the number of whole millimeters (if any) and the number of hundredths of a millimeter, as with an ordinary micrometer, and the number of thousandths of a millimeter given by the coinciding vernier line on the sleeve vernier scale.

For example, a measurement of 5.783millimetres would be obtained by reading 5.5millimetres on the sleeve, and then adding 0.28millimetre as determined by the thimble. The vernier would then be used to read the 0.003 (as shown in the image).

Inch micrometers are read in a similar fashion.

Note: 0.01 millimeter = 0.000393 inch, and 0.002millimeter = 0.000078 inch (78 millionths) or alternatively, 0.0001 inch = 0.00254millimeters. Therefore, metric micrometers provide smaller measuring increments than comparable inch unit micrometers—the smallest graduation of an ordinary inch reading micrometer is 0.001 inch; the vernier type has graduations down to 0.0001 inch (0.00254 mm). When using either a metric or inch micrometer, without a vernier, smaller readings than those graduated may of course be obtained by visual interpolation between graduations.

Calibration: testing and adjusting

Zeroing

On most micrometers, a smallpin spanner

A wrench or spanner is a tool used to provide grip and mechanical advantage in applying torque to turn objects—usually rotary fasteners, such as nuts and bolts—or keep them from turning.

In the UK, Ireland, Australia, and New Zeala ...

is used to turn the sleeve relative to the barrel, so that its zero line is repositioned relative to the markings on the thimble. There is usually a small hole in the sleeve to accept the spanner's pin. This calibration procedure will cancel a zero error: the problem that the micrometer reads nonzero when its jaws are closed.

Testing

A standard one-inch micrometer has readout divisions of 0.001 inch and a rated accuracy of ±0.0001 inch ("one tenth

The decimal numeral system (also called the base-ten positional numeral system and denary or decanary) is the standard system for denoting integer and non-integer numbers. It is the extension to non-integer numbers of the Hindu–Arabic numeral ...

", in machinist parlance).

Both the measuring instrument and the object being measured should be at room temperature for an accurate measurement; dirt, abuse, and low operator skill are the main sources of error.

The accuracy of micrometers is checked by using them to measure gauge block

Gauge blocks (also known as gage blocks, Johansson gauges, slip gauges, or Jo blocks) are a system for producing precision lengths. The individual gauge block is a metal or ceramic block that has been precision ground and lapped to a specific ...

s, rods, or similar standards whose lengths are precisely and accurately known. If the gauge block is known to be 0.75000±0.00005inch ("seven-fifty plus or minus fifty millionths", that is, "seven hundred fifty thou plus or minus half a tenth"), then the micrometer should measure it as 0.7500inch. If the micrometer measures 0.7503inch, then it is out of calibration. Cleanliness and low (but consistent) torque are especially important when calibrating—each tenth (that is, ten-thousandth of an inch), or hundredth of a millimetre, "counts"; each is important. A mere speck of dirt, or a mere bit too much squeeze, obscures the truth of whether the instrument can read correctly. The solution is simply conscientiousness

Conscientiousness is the personality trait of being careful, or diligent. Conscientiousness implies a desire to do a task well, and to take obligations to others seriously. Conscientious people tend to be efficient and organized as opposed to ...

—cleaning, patience, due care and attention, and repeated measurements (good repeatability assures the calibrator that their technique is working correctly).

Calibration typically checks the error at 3 to 5 points along the range. Only one can be adjusted to zero. If the micrometer is in good condition, then they are all ''so near to zero'' that the instrument seems to read essentially "-on" all along its range; no noticeable error is seen at any locale. In contrast, on a worn-out micrometer (or one that was poorly made to begin with), one can "chase the error up and down the range", that is, ''move'' it up or down to any of various locales along the range, by adjusting the sleeve, but one cannot ''eliminate'' it from all locales at once.

Calibration can also include the condition of the tips (flat and parallel), ratchet, and linearity of the scale. ITTC – Recommended Procedures : Sample Work Instructions Calibration of Micrometers. Flatness and parallelism are typically measured with a gauge called an optical flat, a disc of glass or plastic ground with extreme accuracy to have flat, parallel faces, which allows light bands to be counted when the micrometer's anvil and spindle are against it, revealing their amount of geometric inaccuracy.

Commercial machine shops, especially those that do certain categories of work (military or commercial aerospace, nuclear power industry, medical, and others), are required by various standards organization

A standards organization, standards body, standards developing organization (SDO), or standards setting organization (SSO) is an organization whose primary function is developing, coordinating, promulgating, revising, amending, reissuing, interpr ...

s (such as ISO

ISO is the most common abbreviation for the International Organization for Standardization.

ISO or Iso may also refer to: Business and finance

* Iso (supermarket), a chain of Danish supermarkets incorporated into the SuperBest chain in 2007

* Iso ...

, ANSI

The American National Standards Institute (ANSI ) is a private non-profit organization that oversees the development of voluntary consensus standards for products, services, processes, systems, and personnel in the United States. The organi ...

, ASME

The American Society of Mechanical Engineers (ASME) is an American professional association that, in its own words, "promotes the art, science, and practice of multidisciplinary engineering and allied sciences around the globe" via "continuing ...

,ASME B89.1.13 - 2013 MicrometersASTM, SAE,

AIA AIA or A.I.A. or Aia may refer to:

Aia

* Aia, a small town in the Basque province of Gipuzkoa, Spain

* Aia, current Kutaisi, ancient capital of Colchis

* Aia, another name for Aea (Malis), an ancient town in Greece

* ''Aia'', the collected ed ...

, the U.S. military, and others) to calibrate micrometers and other gauges on a schedule (often annually), to affix a label to each gauge that gives it an ID number and a calibration expiration date, to keep a record of all the gauges by ID number, and to specify in inspection reports which gauge was used for a particular measurement.

Not all calibration is an affair for metrology labs. A micrometer can be calibrated on-site anytime, at least in the most basic and important way (if not comprehensively), by measuring a high-grade gauge block and adjusting to match. Even gauges that are calibrated annually and within their expiration timeframe should be checked this way every month or two if they are used daily. They usually will check out OK as needing no adjustment.

The accuracy of the gauge blocks themselves is traceable through a chain of comparisons back to a master standard such as the international prototype of the meter. This bar of metal, like the international prototype of the kilogram, is maintained under controlled conditions at the International Bureau of Weights and Measures

The International Bureau of Weights and Measures (french: Bureau international des poids et mesures, BIPM) is an intergovernmental organisation, through which its 59 member-states act together on measurement standards in four areas: chemistry, ...

headquarters in France, which is one of the principal measurement standards laboratories of the world. These master standards have extreme-accuracy regional copies (kept in the national laboratories of various countries, such as NIST), and metrological equipment makes the chain of comparisons. Because the definition of the meter is now based on a light wavelength, the international prototype of the meter is not quite as indispensable as it once was. But such master gauges are still important for calibrating and certifying metrological equipment. Equipment described as "NIST traceable" means that its comparison against master gauges, and their comparison against others, can be traced back through a chain of documentation to equipment in the NIST labs. Maintaining this degree of traceability requires some expense, which is why NIST-traceable equipment is more expensive than non-NIST-traceable. But applications needing the highest degree of quality control mandate the cost.

Adjustment

A micrometer that has been zeroed and tested and found to be off might be restored to accuracy by further adjustment. If the error originates from the parts of the micrometer being worn out of shape and size, then restoration of accuracy by this means is not possible; rather, repair (grinding, lapping, or replacing of parts) is required. For standard kinds of instruments, in practice it is easier and faster, and often no more expensive, to buy a new one rather than pursue refurbishment.See also

*Filar micrometer

A filar micrometer is a specialized eyepiece used in astronomical telescopes for astrometry measurements, in microscopes for specimen measurements, and in alignment and surveying telescopes for measuring angles and distances on nearby objects. Th ...

* Vernier scale

A vernier scale, named after Pierre Vernier, is a visual aid to take an accurate measurement reading between two graduation markings on a linear scale by using mechanical interpolation, thereby increasing resolution and reducing measurement unce ...

References

Bibliography

* . Reprinted by McGraw-Hill, New York and London, 1926 (); and by Lindsay Publications, Inc., Bradley, Illinois, (). * ISO 3611: "Geometrical product specifications (GPS). Dimensional measuring equipment. Micrometers for external measurements. Design and metrological characteristics" (2010) * BS 870: "Specification for external micrometers" (2008) * BS 959: "Specification for internal micrometers (including stick micrometers)" (2008) * BS 6468: "Specification for depth micrometers" (2008)External links

micrometer simulator with zero error.

* ttp://www.miniphysics.com/how-to-read-a-micrometer-screw-gauge.html How to read a micrometer screw gaugebr>How its made, micrometer

{{Authority control Length, distance, or range measuring devices